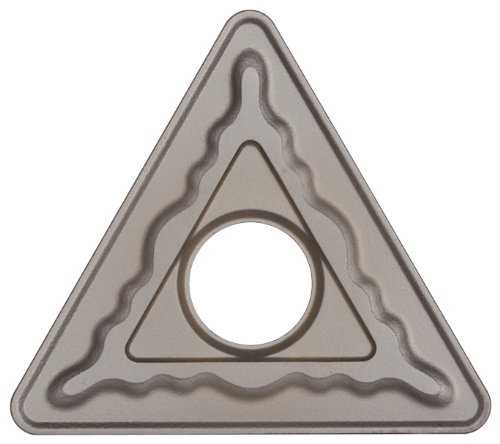

The Sandvik Coromant TNMG GC4205 indexable turning insert with a choice of PR, MR, PM, QM, or PF chipbreaker style has a triangle shape with a 60-degree cutting angle, providing high wear resistance for roughing to finishing of steel in good machining conditions. This double-sided negative insert has a chip groove on both sides, a hole in the center and six cutting edges. It has strong edges, zero clearance, and is a better choice for external turning than a positive insert. GC4205 grade is a combination of carbide and a coating of titanium carbonitride (TiCN), aluminum oxide (Al2O3) and titanium nitride (TiN) applied through medium temperature chemical vapor deposition (MTCVD), which has hardness for high wear resistance, and excellent resistance against crater wear and plastic deformation in wet and dry conditions. MTCVD coatings are deposited at lower temperatures than CVD coatings. The lower temperatures reduce cracks in the coating and provide increased toughness and smoothness without limiting wear resistance. The coating also provides shock resistance during interrupted cuts.

The TNMG GC4205 is available with a choice of five chipbreakers: PR, MR, PM, QM, or PF. The PR and MR chipbreakers are designed for high cutting speeds and feed rates. The PR chipbreaker has a wider range of cutting depths than the MR. The PM and QM chipbreakers are designed for medium-machining cutting depths and feed rates. The QM chipbreaker should be chosen over the PM chipbreaker when more machining stability is required. The PF chipbreaker is designed for low cutting depths and feed rates and is a good choice when low cutting forces or high quality surface finish is required.

Tolerance of the distance from the base to the tip of the triangle is + or - 0.002” to 0.005”. Tolerance of the theoretical diameter of the insert is + or - 0.002” to 0.005”. Insert thickness tolerance is + or - 0.005”. Different insert shapes and sizes may have different inscribed circle (iC) measurements, which are related to the insert’s range of cutting depths, speeds, lead angle, and feed rates. The inscribed circle is the largest circle that can be drawn within the edges of the insert shape. In general, as the insert size and iC become larger, the maximum cutting depth increases. The cutting depth influences the metal removal rate, number of cuts, chip evacuation, and power required when using the insert.

Indexable inserts are small cutting tools designed to remove material in external and internal cutting applications such as turning, milling, drilling, and grooving. They are held by an insert holder, have multiple cutting edges, and can be rotated when one edge wears down. Multiple inserts can be used to accomplish a variety of cuts in one operation. An insert is either positive or negative, which refers to the rake or clearance angle at which the insert removes material. Inserts are coded according to their specific cutting and application capability (e.g. VNMG 16 04 04-QM). Each part of the code represents details of the insert shape, nose angle, clearance, tolerance, size, geometry, grade, and chipbreaker style.

Sandvik Coromant manufactures tools for turning, milling, and drilling. The company, headquartered in Sweden, makes tools used throughout the metalworking field, including the automotive and aerospace, die and mold, and general engineering industries. Sandvik Coromant inserts meet International Organization for Standardization (ISO) and American National Standards Institute (ANSI) standards.

Matching Inserts to Holders

These inserts are part of the Sandvik Coromant TMax P Negative Insert family, which means they can be used with CoroTurn RC, a clamp-style insert holding system. This system is for use when stability and security are essential for productive turning of large components. The system is mostly used for external turning, from roughing to finishing, but also for internal turning.